Our Services

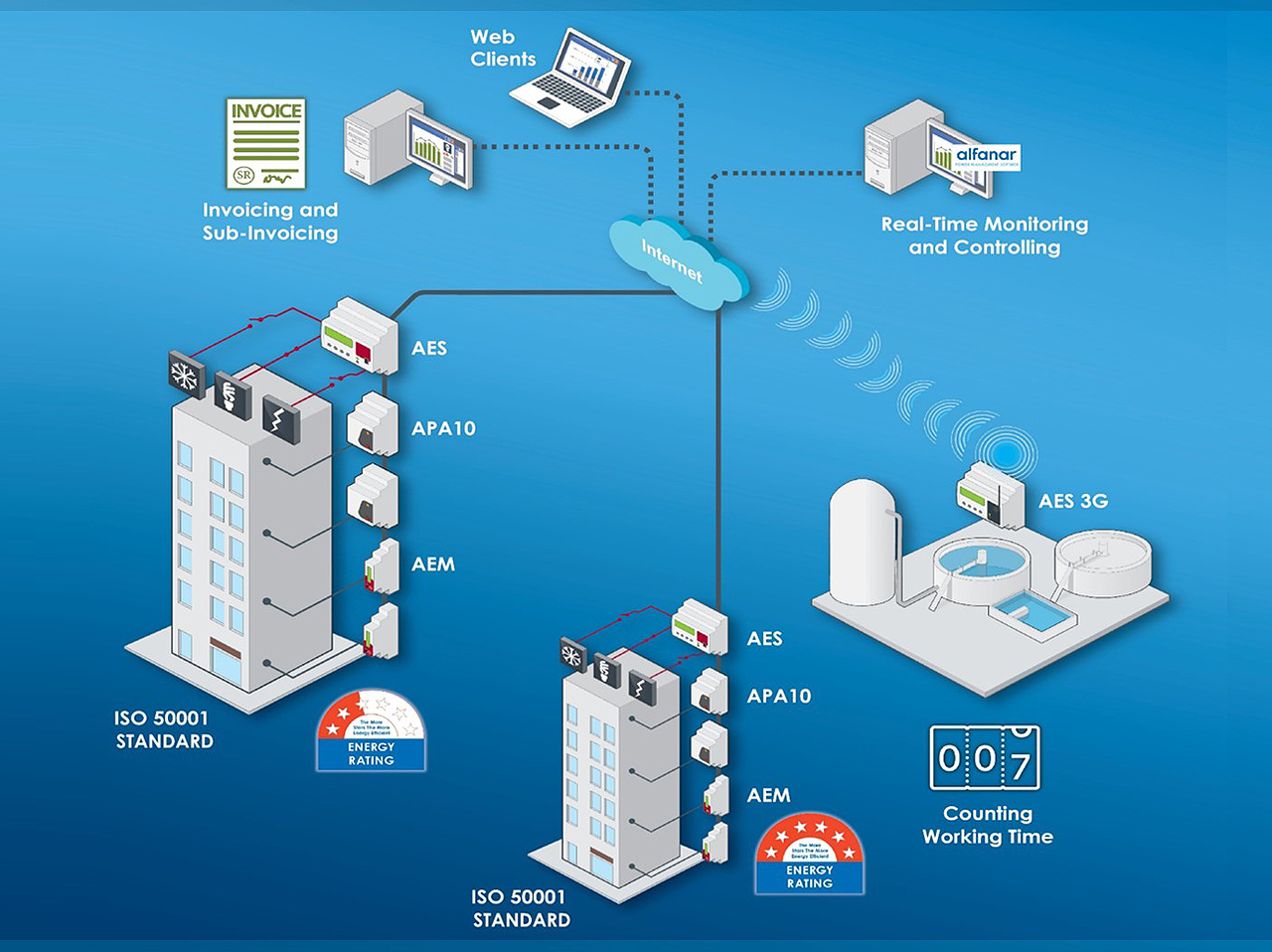

This involves improving our energy networking system by providing smart control and communicative data technologies to give consumers control of their energy needs. We provide end to end project design and services for customised Energy Solutions.

In a move towards a reliable, affordable and the best optimized Energy network, HIS Group helps high energy consumers to achieve a reliable, cost efficient energy through smart energy management systems. This involves improving our energy networking systems by providing smart control and communicative data technologies to give consumers control of their energy needs and costs. We Provide End to End project design, Engineering, commissioning, testing and services for customer Based Energy Solutions.

In terms of production management solutions, we are both bold and resourceful. Solving your problem and hustling is what we love to do. We conceptualize and create solutions which are relevant to the present & future needs.Production management system is the basis of modern factory information management for safe production, we establish the production management system and assist enterprises in fulfillment of business plans, construction of their production orders, deployment of production resources, assurance of safe production and realization of their production goals,Pharma, Food industries, Beverages industries, heavy asset processing industries, such as power generation, chemical industry, iron ,steel and nonferrous metal to constantly improve the corporate level of intelligent plant production and better the enterprise management performances.

There are various types of reports that are made using PMS ,stated below

Visitors have always been an important aspect to every industry whose entry in industry needs to be managed, to keep a record and have a security check on the,. Helpful innovative solutions have come up with the management of visitors into manufacturing industry or a corporate office. This system takes care of all the factors required to manage the visitor's entry into any organization.

Distribution Management efficiency has a direct correlation to inventory optimization throughout the supply chain. Accomplishing this requires you to truly maximize inventory flow not only inside your warehouse , but also as inventory enters and leaves the yard outside . Our Warehouse Management system (WMS) provides real-time information, intelligent work direction, and complete visibility of trucks , trailers , drivers , goods and materials? from the moment they arrive at the gate to the moment they leave your facility.